Beverage Filling Machine Wholesale, Filling Machine Suppliers——RISTON BEVERAGE MACHINE. This beverage filling line consists of five steps: preform feeding, blowing, labeling, filling and cap feeding. Those five parts integrates into a single system, provide customers with continuous production optimization and performance enhancement.

Chiller:

It is used for high-speed cooling after food processing to adapt it to packaging requirements. There is also a temperature for controlling the fermented food.The chiller is a cooling water device that provides constant temperature, constant current and constant pressure. The temperature of the chiller backwater should not be higher than 40 degrees. The higher the return water temperature, the greater the damage to the compressor. The operation of the chiller system is through three interrelated systems of refrigerant circulation system, water circulation system and electrical automatic control system. The chiller is divided into a low temperature chiller and a normal temperature chiller in temperature control, and the normal temperature is generally controlled within a range of 0 to 35 degrees. The temperature of the cryostat is generally controlled in the range of 0 degrees to minus 100 degrees.

Mixing tank:

The mixing tank has the advantages of energy saving, corrosion resistance, strong production capacity, convenient cleaning and simple structure. It is mainly used for mixing of dairy products and sugar and other elements and various drugs. It is an indispensable equipment for dairy, beverage and pharmaceutical factories. It is used to mix the juice, concentrated juice that have already been taken out with other necessary ingredients such as sugar, flavor, food coloring, etc., and mix them, and add proportional pure water during the preparation process. The beverage can be evenly distributed, and no solidification of the particles occurs after the filling, so that the juice beverage can maintain the quality change without flocculation for a long period of time.All parts contact with beverage are made of stainless steel 304 material, it meets food grade hygiene requirements and is durable.Polished cylinder with a stirring paddle for stirring.

Buffer Tank:

The buffer tank has the functions of heating, cooling, heat preservation and metering. It is a necessary equipment for intermediate buffering, liquid storage and reaction commonly used in pharmaceutical, bioengineering, food, beverage, fruit wine, condiment, fine chemical, oil and fat industries. Buffer tanks also have higher requirements for sanitary grades. Generally, they must meet the requirements of sterility, and the discharge is clean and no materials remain. Buffer tanks used in pharmaceuticals and foods are generally sterilized and must meet GMP standards.

CIP System:

This Clean In Place system container tanks, pipes, pumps, filters, etc., and the entire production line, without the need for manual disassembly or opening, sprays a certain temperature of cleaning liquid through a closed pipe to the inner surface of the equipment within a predetermined time. To achieve the purpose of cleaning. CIP cleaning is also called cleaning positioning or positioning cleaning. In-situ cleaning refers to a method of washing the food and the required contact surface with a high-temperature, high-concentration cleaning solution without disassembling or moving the device.Compact design, easy installation, maintenance and commissioning; pneumatic components and electrical components are all imported materials, stable and reliable performance, modular structure with functional blocks, can be divided into manual control, automatic selection, touch screen prompt operation, intuitive and easy to understand.Remove drug residues, prevent microbial contamination, and avoid batch effects.Reduce cleaning costs and consume less water, cleaning agents and steam.

Palletizer:

The palletizer is a carton that has been loaded into a container, placed on a pallet, a pallet (wood, plastic) according to a certain arrangement code, and automatically stacked, can be stacked in multiple layers, and then pushed out, so that the forklift can be transported to the warehouse for storage. This equipment adopts PLC+ touch screen control to realize intelligent operation management, which is simple and easy to master. Can greatly reduce labor and reduce labor intensity. The palletizing machine is a device that automatically transports the material bags, cartons or other packaging materials conveyed by the conveyor into the crucible according to the working mode of the customer's process, and transports the material into the crucible.

Slide way Can Washer:

It consists of an inlet turnover, a sprinkler, an exit turnover, a rack. The empty cans unloaded from the empty tank unloader enter the slide of the machine. Due to the drop and the gravity of the empty can, the empty can slides down the slide by itself, and the empty can is inverted when it slides down into the can. At this time, the water tank is sprayed with water to the tank to wash the empty tank. The empty cans continued to slide down to the cans and turned over again, turning the cans up again and entering the filling operation.

Blowing Dryer:

The automatic air knife dryer is mainly used to dry the bottle after filling , and then labeling.

It uses a stirring hot fan and a circulating hot air knife. In addition to the environmental protection and energy saving advantages of the hot air circulation, it can directly heat, control the temperature, adjust the air volume and the wind direction, and achieve hot air drying more quickly and more uniformly. , heat shrinkage, heat treatment effect.

The Coding Machine:

This coding machine is a batch coding machine designed for high-speed applications and around the clock operation.It is the standard for high throughput coding applications in production environments around the world.Long running time between preventive maintenance up to 12,000 hour core life.Automatic cleaning print head for fast start ups, even after extended shutdown.Laser coding machine has higher coding speed. The coding speed can reach to 7000mm/s.Higher coding efficiency to integrate with different production lines. No consuming materials. You just need to change wearing parts occasionally, no pollution to environment.Easy to operate, having powerful software to make coding flexible and convenient.Long working lifetime, suitable for long and continuous working. Permanent signs and marks for stronger anti-fake functions. Laser coding machine is a cost-effective coding machine.

UHT:

It is a method of sterilizing food by heating in a very short time (heating with 135 ~ 150 ° C for 2 ~ 3 seconds). This temperature can kill spores left in milk. This is the most common way to There is milk sterilized, but this process is equally applied to juice, butter, soy milk, yogurt, wine, soup, honey and soup.With high reuse efficiency,tight structure design fine looking and well controlled temperature; discharge temperature of this machine can be self controlled so it is available for the hot filling procedure and meanwhile for aseptic cold filling.

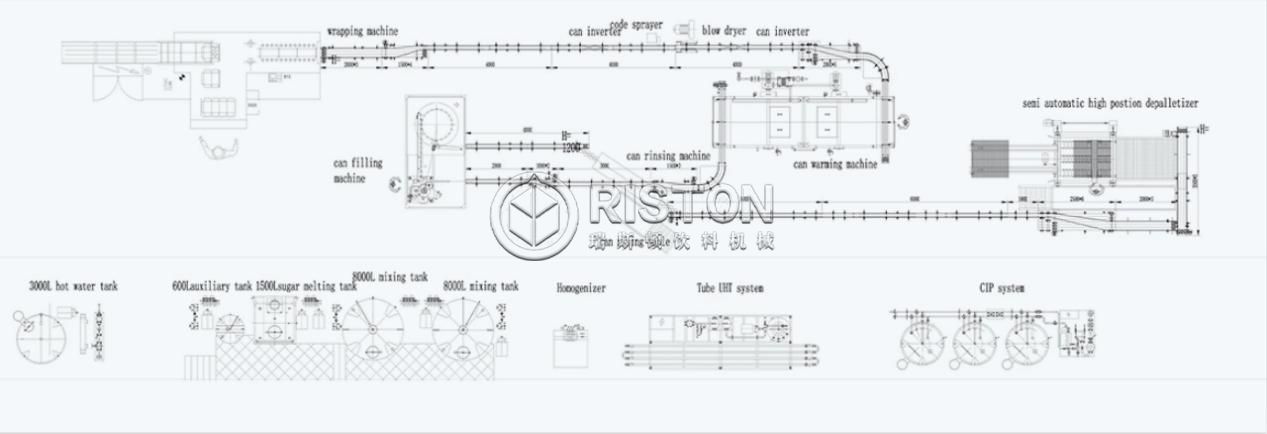

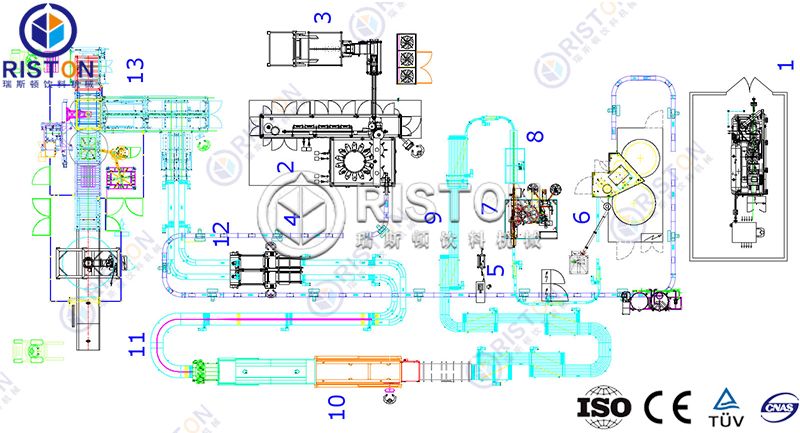

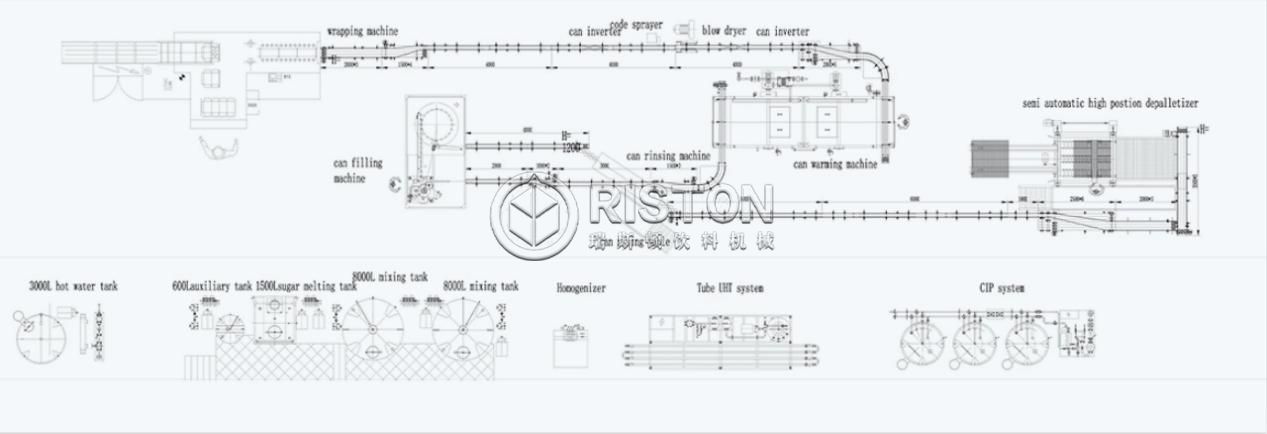

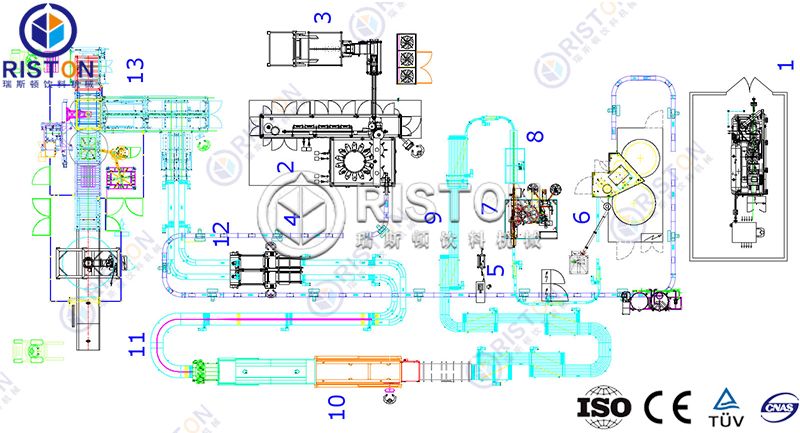

CAD Configurations:

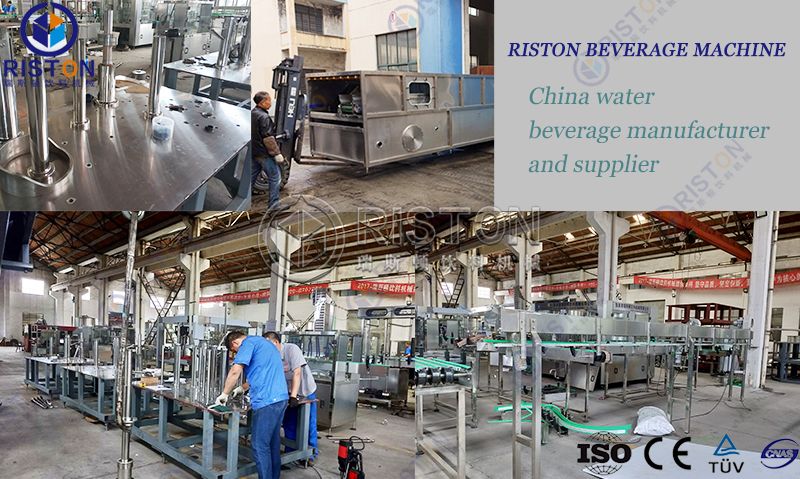

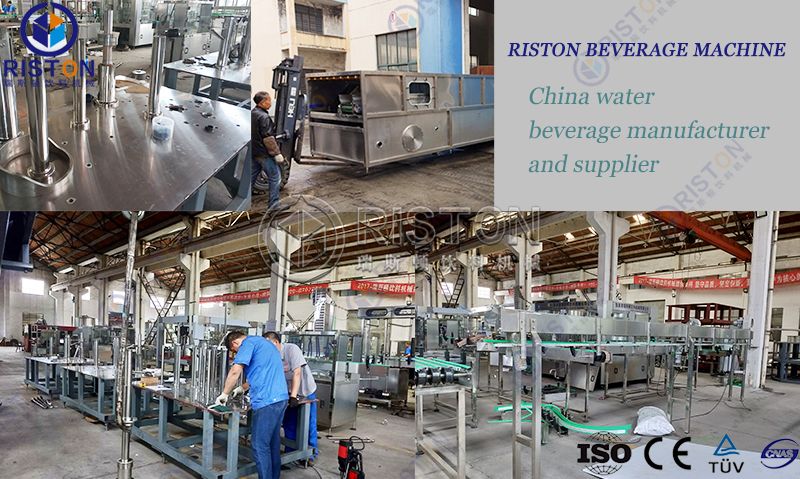

Our Factory:

ZHANGJIAGANG RISTON BEVERAGE MACHINE CO.,LTD is located in the Yangtze river delta region in the south of jiangsu golden waterway, specializing in the production of complete sets of water filling equipment, fruit juice filling equipment, carbonated beverage filling equipment, labeling & packaging equipment, bottle blowing equipment, drinking water treatment equipment, and kinds of auxiliary machines and so on.

In order to meet different demand of domestic and abroad water beverage beer industry, RISTON company develop varieties of intelligent full automatic filling production line. Machine system development force is strong; Machine system design is advanced; Spare parts of the machines are high precision; Before-sales and after-sales service is perfect. We have a clear division of labor in the organizational structure and a positive culture. RISTON will provide you a complete set of turn-key project, make you save time save labor save money.

RISTON can Provide the Whole Factory Design, Machine Manufacture, Installation & Debugging, Beverage Formula, Production Instruction, Technician Training, Purification workshop planning, After-sales Maintenance, Lifelong Technical Support One-stop Service and turn-key project.

If you want to produce high quality water or beverage, please choose RISTON beverage machine, RISTON can make you realize the lowest ownership cost, the longest machinery use life, make your water or beverage be inexhaustible wealth.

Customer’s Factory:

Our Customers: