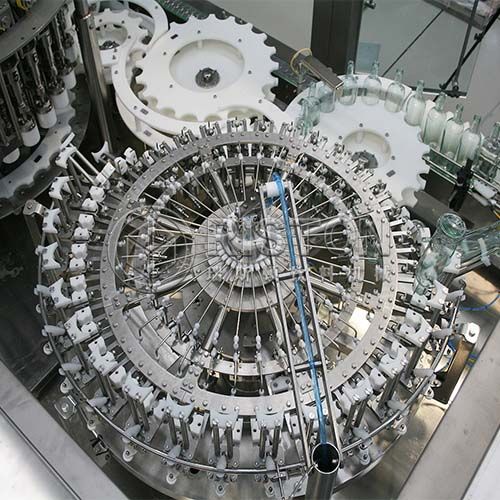

Introduction of filling production line equipment

Introduction of filling production line equipment:

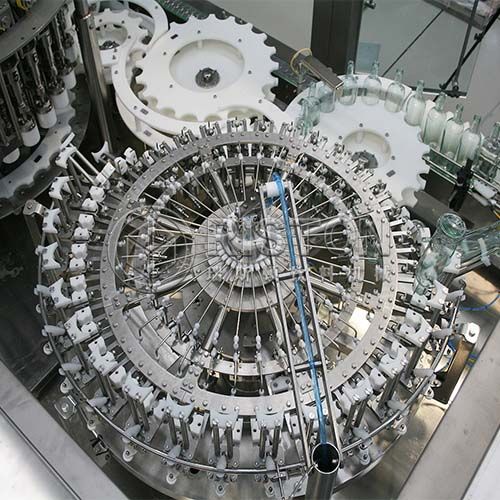

The switch is set to the active operation mode. Once started, the drive generator of the conveyor belt is started and it always insists on stopping the switch operation, or it is stopped when the beverage bottles are transferred to the filling production line. After the bottle is filled with the beverage and the lid is closed, the conveyor drive motor must be activated actively, and insist that the next beverage bottle to be filled is transferred to the filling equipment or the switch operation is stopped.

When the bottle is positioned under the filling production line equipment, after a pause of one second, the filling production line starts to work. After the large bottle is filled for 8 seconds, the small bottle is filled for 5 seconds. After the filling process is completed, the lid is closed. 2 seconds. There should be an alarm display during the entire capping process, and no alarm will be given after the capping is completed. The alarm mode is that the red light flashes at 0.5 second intervals.

Beverage filling machinery is on the packaging, regarding the small bottles: 40 bottles are large bags, 30 bottles are medium bags, 20 bottles are small bags. About big bottles: 20 bottles are big bags, 15 bottles are medium bags, and 10 bottles are small bags.

It can complete the active counter clearing of the produced products.

RISTON is an integrated beverage machinery manufacturer integrating research, development and production. It has 18 years of experience in the industry.