Beverage Filling Machine Wholesale, Filling Machine Suppliers——RISTON BEVERAGE MACHINE. This beverage filling line consists of five steps: preform feeding, blowing, labeling, filling and cap feeding. Those five parts integrates into a single system, provide customers with continuous production optimization and performance enhancement.

CO2 Carbonated Drink Mixer:

This Stainless Steel Automatic CO2 Carbonated Drink Mixer is used for Carbonated and proportion mixing of various carbonated beverages (water, syrup, carbon dioxide), such as lemon, cola, juice, wine, sparkling wine, etc., is the main equipment in beverage complete equipment (especially in medium and high-grade Key equipment for beverages.)This machine is low resistance loss, high efficiency, low energy consumption, simple structure, and reliable performance and low noise. Easy to adjust, the machine can easily adjust the output and the ratio of syrup to water without replacing other parts.This machine adopts carbon dioxide deoxidation to make deoxidized water have better pre-carbonization effect.This machine can easily adjust the gas content and adjust it according to the requirements of the gas content of the beverage through appropriate operation.The machine is equipped with a complete automatic control system, with the advantages of coordinated action, simple structure, continuous and high degree of automation.

Syrup Cooler:

The filtered syrup is injected into the syrup cooler, and the evaporator tube of the cooler is matched with the refrigeration unit with stirring. Reduce the syrup in the cooler to 3-5 ° C to ensure the mixed gas content of the beverage.

Sugar Syrup Filter:

The syrup filter can be used as a filter for juice, beverage and water to meet the requirements of the syrup filter medium. In addition to diatomaceous earth, the filter medium can also be made of perlite, activated carbon or the like.It is Widely used for the filtration of juice, beverages, beer, wine and water. All seals of the machine are made of high temperature resistant silicone parts (food grade).The stainless steel centrifugal pump uses a water-cooled mechanical seal to effectively extend the life of the mechanical seal.Less moving parts, low maintenance costs, only need to replace the seals.

Sugar Melting Pot:

This sugar melting pot is made of acid-resistant and heat-resistant 304 stainless steel with safety valve and electric control box. Good appearance, easy to install, easy to operate, safe and reliable.It has large heating area, uniform heating, high thermal efficiency, short boiling time of liquid, and easy control of heating temperature. Widely used in food processing such as candy pharmacy, dairy wine, cakes, beverages, candied fruit, canned food, etc..The device consists of a cylindrical stainless steel inner cylinder head forming a heat transfer interlayer. The outside is polished with stainless steel and the surface is beautiful. The dissolved material and the cold water are placed in the pot, and the steam is introduced into the interlayer to achieve the purpose of heating and melting. A pressure gauge safety valve is placed on the pipe that communicates with the mezzanine to measure the pressure in the interlayer and to ensure safe production.

Carbon Dioxide Filter:

This equipment is mainly used in the beverage production industry, and is also suitable for the purification of carbon dioxide gas in the chemical, food, brewing and other industries. The utility model has the advantages of reasonable design, simple structure, safety and reliability, beautiful appearance and strong corrosion resistance.This product is made of high quality stainless steel plate, stainless steel joint, stainless steel filter plate, sterilization film, electrostatic foam particles, adsorbent, oxidant, and is equipped with flow meter, pressure gauge and valve. It has reasonable design, novel style and simple structure. Safe, hygienic, convenient and practical.The carbon dioxide gas in the cylinder is purified by this type carbon dioxide purifier, which can effectively purify the harmful substances in the carbon dioxide gas, and has a positive effect on improving the quality of the gas-containing beverage product and ensuring human health.

CIP System:

This Clean In Place system container tanks, pipes, pumps, filters, etc., and the entire production line, without the need for manual disassembly or opening, sprays a certain temperature of cleaning liquid through a closed pipe to the inner surface of the equipment within a predetermined time. To achieve the purpose of cleaning. CIP cleaning is also called cleaning positioning or positioning cleaning. In-situ cleaning refers to a method of washing the food and the required contact surface with a high-temperature, high-concentration cleaning solution without disassembling or moving the device.Compact design, easy installation, maintenance and commissioning; pneumatic components and electrical components are all imported materials, stable and reliable performance, modular structure with functional blocks, can be divided into manual control, automatic selection, touch screen prompt operation, intuitive and easy to understand.Remove drug residues, prevent microbial contamination, and avoid batch effects.Reduce cleaning costs and consume less water, cleaning agents and steam.

The Coding Machine:

This coding machine is a batch coding machine designed for high-speed applications and around the clock operation.It is the standard for high throughput coding applications in production environments around the world.Long running time between preventive maintenance up to 12,000 hour core life.Automatic cleaning print head for fast start ups, even after extended shutdown.Laser coding machine has higher coding speed. The coding speed can reach to 7000mm/s.Higher coding efficiency to integrate with different production lines. No consuming materials. You just need to change wearing parts occasionally, no pollution to environment.Easy to operate, having powerful software to make coding flexible and convenient.Long working lifetime, suitable for long and continuous working. Permanent signs and marks for stronger anti-fake functions. Laser coding machine is a cost-effective coding machine.

Blowing Dryer:

The automatic air knife dryer is mainly used to dry the bottle after filling , and then labeling.It uses a stirring hot fan and a circulating hot air knife. In addition to the environmental protection and energy saving advantages of the hot air circulation, it can directly heat, control the temperature, adjust the air volume and the wind direction, and achieve hot air drying more quickly and more uniformly. , heat shrinkage, heat treatment effect.

Automatic packaging machine:

The packaging system is an intelligent automatic cartoning machine, which uses a high-speed distribution device to package various containers, packaging plastic flat bottles, round bottles, irregular shaped bottles, glass bottles of various sizes, round bottles, oval Bottles, square cans and paper cans, etc., are also applicable to boxes with partitions. The bottle body is clamped by the bottle holder and placed in the opened carton. When the gripper is lifted, the carton is discharged and sent to the sealing machine. The machine is controlled by a PLC touch screen. This assembly line is very convenient for operation, management, reduction of production personnel and labor intensity, and is an indispensable equipment for automated scale production.

Palletizer:

The palletizer is a carton that has been loaded into a container, placed on a pallet, a pallet (wood, plastic) according to a certain arrangement code, and automatically stacked, can be stacked in multiple layers, and then pushed out, so that the forklift can be transported to the warehouse for storage. This equipment adopts PLC+ touch screen control to realize intelligent operation management, which is simple and easy to master. Can greatly reduce labor and reduce labor intensity. The palletizing machine is a device that automatically transports the material bags, cartons or other packaging materials conveyed by the conveyor into the crucible according to the working mode of the customer's process, and transports the material into the crucible.

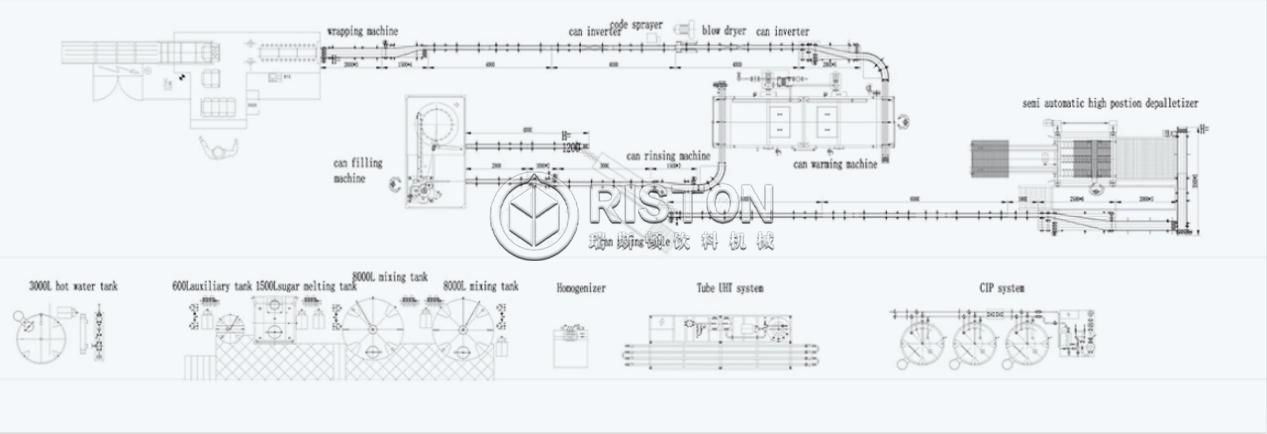

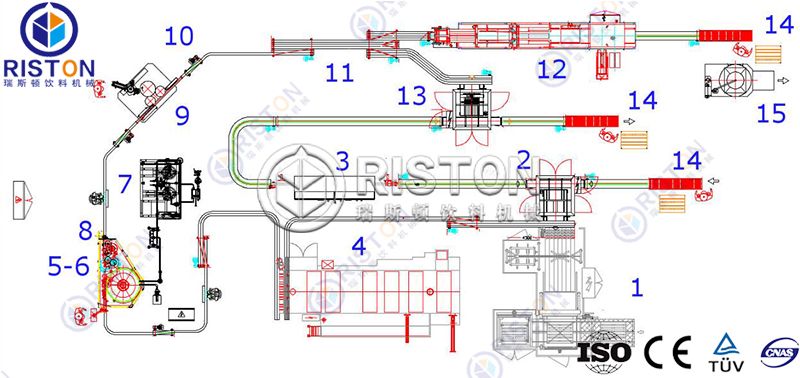

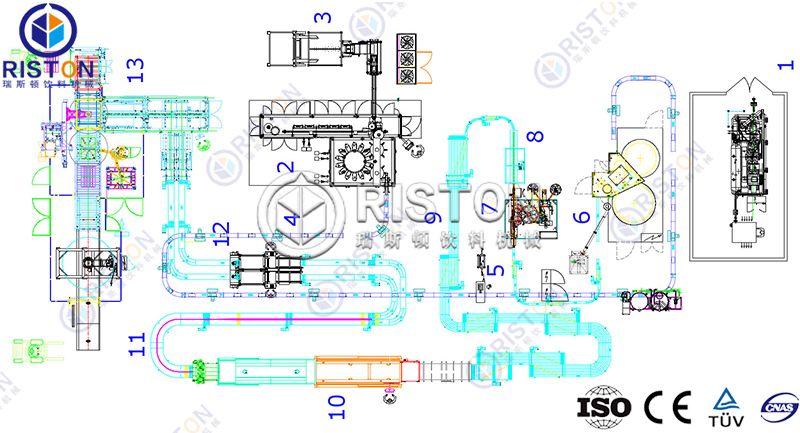

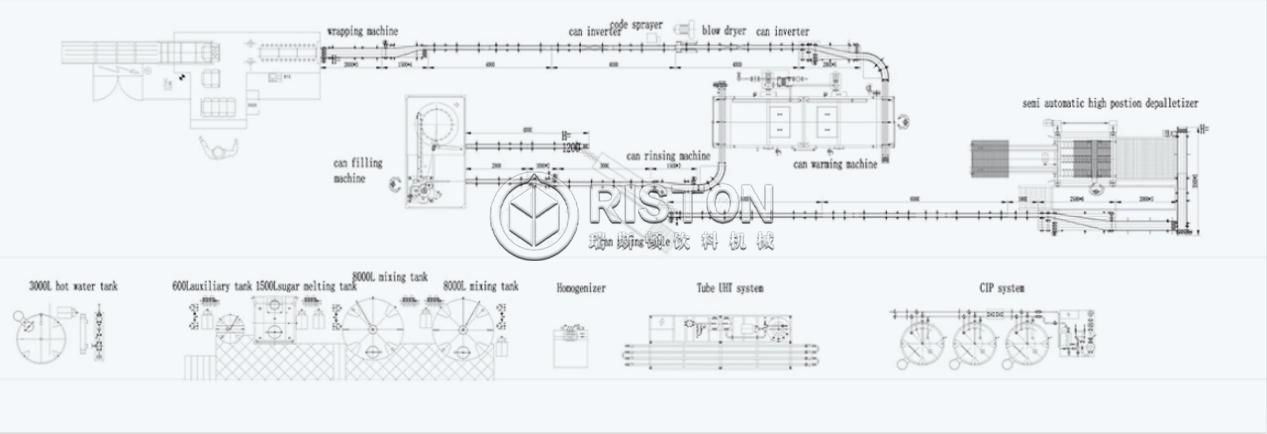

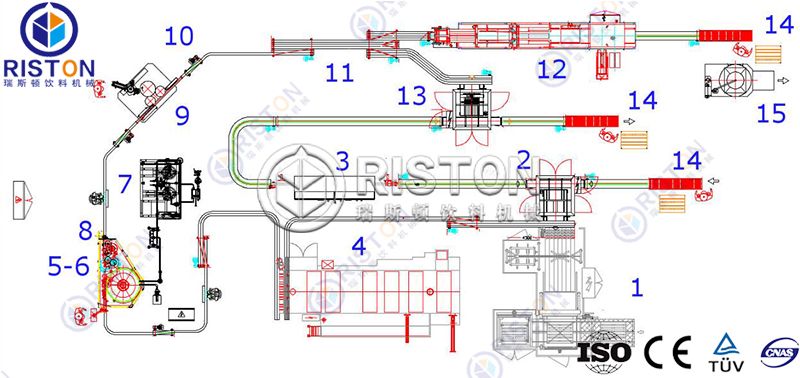

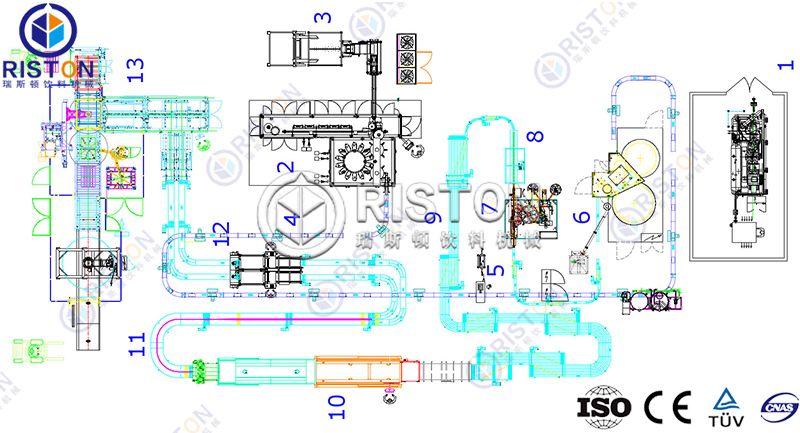

CAD Configurations:

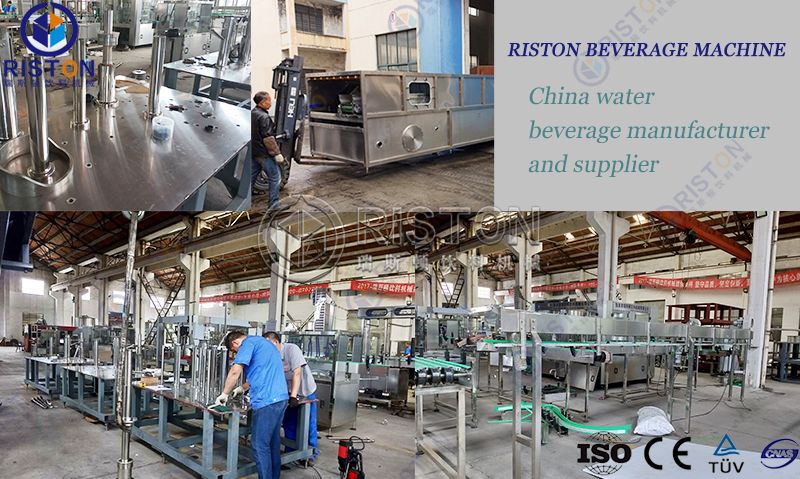

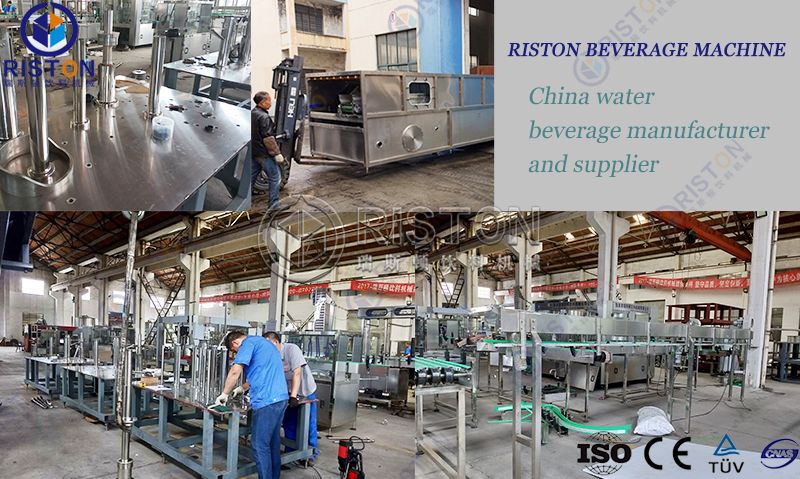

Our Factory:

ZHANGJIAGANG RISTON BEVERAGE MACHINE CO.,LTD is located in the Yangtze river delta region in the south of jiangsu golden waterway, specializing in the production of complete sets of water filling equipment, fruit juice filling equipment, carbonated beverage filling equipment, labeling & packaging equipment, bottle blowing equipment, drinking water treatment equipment, and kinds of auxiliary machines and so on.

In order to meet different demand of domestic and abroad water beverage beer industry, RISTON company develop varieties of intelligent full automatic filling production line. Machine system development force is strong; Machine system design is advanced; Spare parts of the machines are high precision; Before-sales and after-sales service is perfect. We have a clear division of labor in the organizational structure and a positive culture. RISTON will provide you a complete set of turn-key project, make you save time save labor save money.

RISTON can Provide the Whole Factory Design, Machine Manufacture, Installation & Debugging, Beverage Formula, Production Instruction, Technician Training, Purification workshop planning, After-sales Maintenance, Lifelong Technical Support One-stop Service and turn-key project.

If you want to produce high quality water or beverage, please choose RISTON beverage machine, RISTON can make you realize the lowest ownership cost, the longest machinery use life, make your water or beverage be inexhaustible wealth.

Customer’s Factory:

Our Customers: