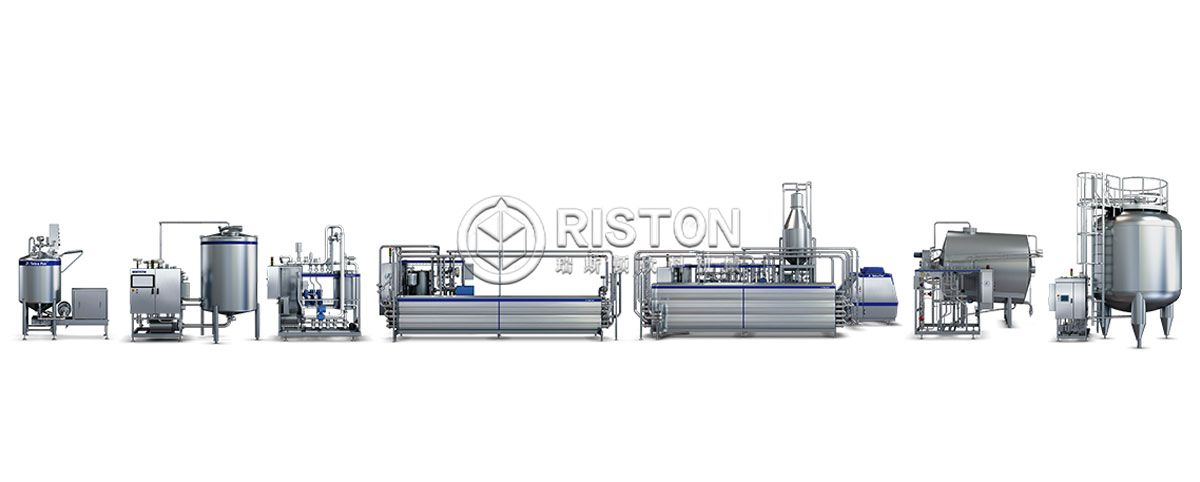

Fruit and Vegetable Washing Machine:

1. The whole machine is made by full stainless steel. It is the special machine for washing & cleaning food.

2. The vegetable and fruit in the water channel is scattered, rolled, cleaned and delivered under high pressure water and powerful bubble.

3. The sand will fall to Isolation warehouse on the bottom and don't cause pollution again. The debris and worms on the water will be collected by net.

4. Water recycling system is equipped under the conveyor belt. Filter sieve will stop the impurity to enter into the water tank. Then the purified water will be brought back to the washing machine, reducing significantly the overall water consumption.

5. It consists of motor & speed reducer, water pump, air pump, conveyor belt, washing tank, water jet, water pipe, valve, control panel, etc.